Pioneers of the Circular Economy

The company has developed strategies that both improve utilization of sustainable energy as well as strengthen supply chains and markets for cleaner energy over time.

problems and challenges into chances!

We are offering innovative and cutting edge small scale biogas plants that are suitable for homes and small farms

Our innovative systems are tested, proved and awarded and coming in different sizes from 2m3 to 7 m3

Also we are providing biogas system components including piping, filters biogas stoves and its spare parts

Medium and community Scale Biogas plants

We are offering Medium Size biogas plants that are suitable for rural communities and medium farms also it can be utilized in Schools and restaurants.

Our medium scale biogas plants are efficient and flexible and can be equipped with piping system and network also can produce biogas for limited electricity purposes

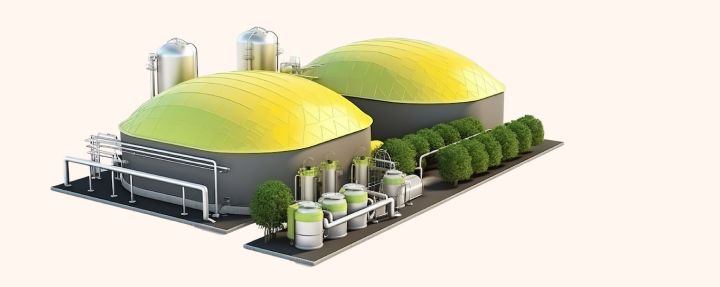

Large Scale Biogas Plants

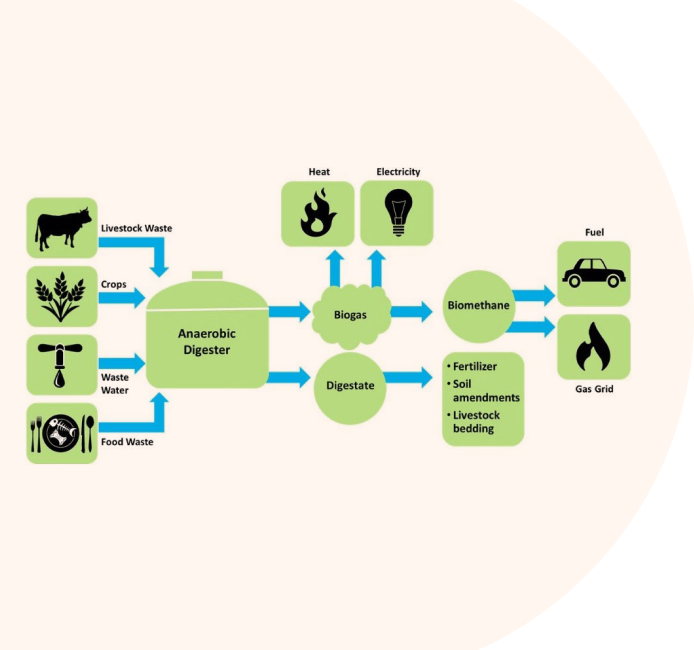

BioTreasure specializes in sustainable energy and environmental solutions through integrated solid waste management. We reduce waste impact by recycling and converting waste, including managing solid waste through methods like anaerobic digestion, composting, and land application. We handle a variety of organic wastes, including MSW, cow dung, poultry waste, paddy straw, agricultural waste, and food waste, converting them into energy.

- LIQUID WASTE TO BIOGAS

- OTHER INDUSTRIAL WASTE WATER TO BIOGAS

- MUNICIPAL SOLID WASTE

- FOOD & KITCHEN WASTE TO BIOGAS

Liquid wastes are wastes generated from industries which process the food, oil extraction unit’s, food processing units and pulping industries, starch extraction industries etc. The liquid waste if left untreated pollutes the environment and the ground water. This has organic content, which has an energy value. The COD and BOD levels determine the amount of biogas that will be produced. This organic waste when subjected to anaerobic conditions yield biogas which can either be converted to electricity for in-house applications or converted to steam which can be used in the process requirement of the industries.

We provide complete turnkey solutions for all other industrial waste waters to meet the local Environmental Regulations and Client Sustainability requirements. We provide tailor made solutions based on inlet and outlet requirements to reduce CAPEX and OPEX of the project. We do upgradation of the existing treatment facilities to meet the discharge norms.

MSW (Municipal solid waste) handling and disposal are big concern in urban areas where local government and municipalities facing issues due to lack of proper places for conventional disposal / land fill areas and environmental problems. As conventional practices, most of the MSW will be land filled and part will be recycled, combusted and composted (organic fraction).

We are providing suitable solutions for handling MSW from Municipalities to cities to convert MSW to Biogas Energy through Anaerobic Digestion. This will reduce the quantity of material being land filled, stabilize the organic material before disposal in order to reduce Environmental impacts from air and water emissions and recover energy.

Food wastes are rich in organic matter and are nuisance for disposal because of space constraint and release of methane during degradation of organics. We are providing solutions for domestic and industrial food & kitchen waste. Food waste entering the plant shall be pre-sorted to separate waste such as plastic, aluminium foils, iron etc then fed into food crusher for size reduction then transferred to slurry tank to prepare 10% concentration.

Quick Links

Reach Us

- +967-772872277 (WhatsApp)

- [email protected]

- Bin Halabi Building, 6th Fl. Khazzan St. Mukalla, Yemen